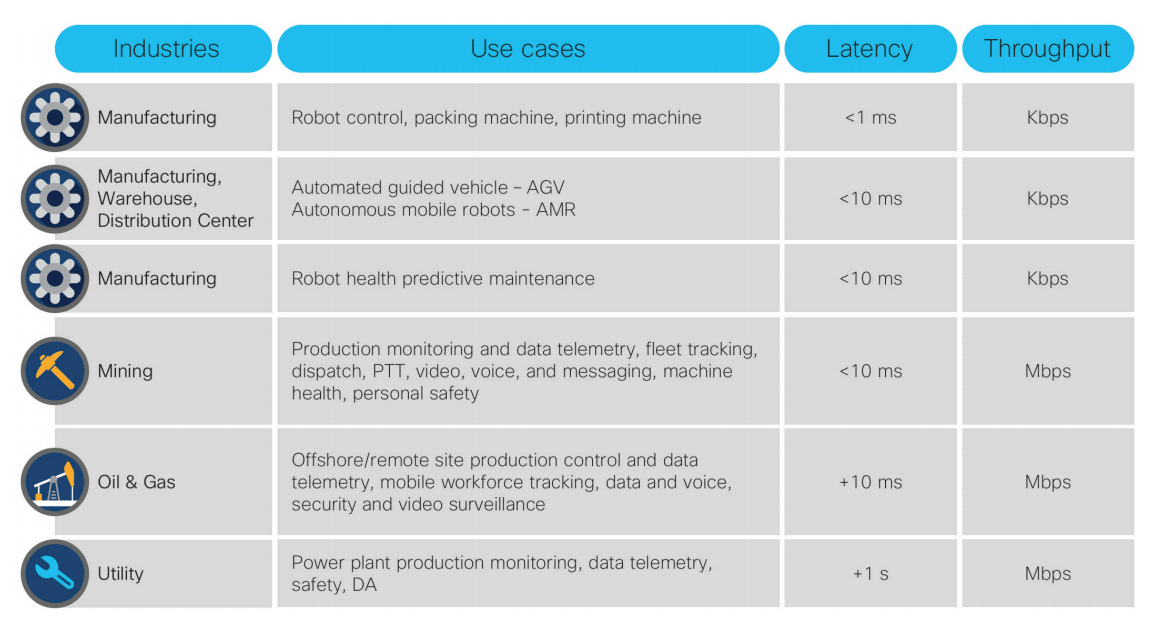

IoT applied to industry will allow people to connect to the Internet in myriad ways. Today, most people connect to the Internet through devices (PCs, tablets, televisions and smartphones) and social networks (Facebook, Twitter, LinkedIn and Pinterest). As the Internet evolves into the IoT, people will connect in more relevant and valuable ways.

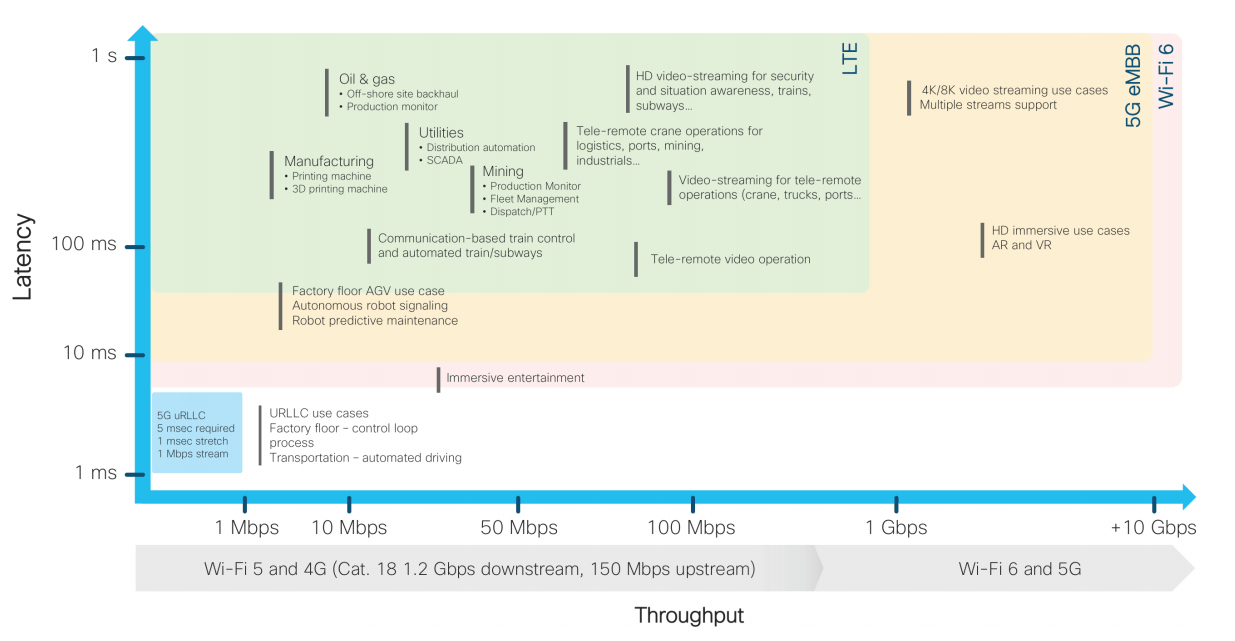

It is convenient to take into account the initial design parameters such as high performance, low delay, high capacity, generally considering Wifi version 6 and 5G, both standards promise better performance, where version 6 is usually considered for indoor environments such as stadiums, centers of conventions, productive areas etc. Since it has improvements to support high densities of connected devices on the other hand, we have 5G that is designed for outdoor networks with fixed radios for interconnection of buildings, drones, Smart cities, which makes it the preferred method for outdoor networks.